[December 6, 2023]

Production Speed and Scale to Deliver Intelligent, Affordable Mass

“The factory is the machine that builds the machine.” -Elon Musk

The Pentagon’s recently-announced $1 billion “Replicator” program – dubbed the “generational challenge to American society” by Deputy Defense Secretary Kathleen Hicks – is aimed squarely at countering China’s numerical edge by leveraging attritable, intelligent mass to tip the balance in the United States’ favor. Shield AI stands prepared to rise to the challenge, drawing inspiration from Elon Musk’s approach to building a well-coordinated factory “machine” to satisfy the DoD’s increasing need for cost-effective, intelligent UAS platforms that can function in GPS- and communications-compromised areas.

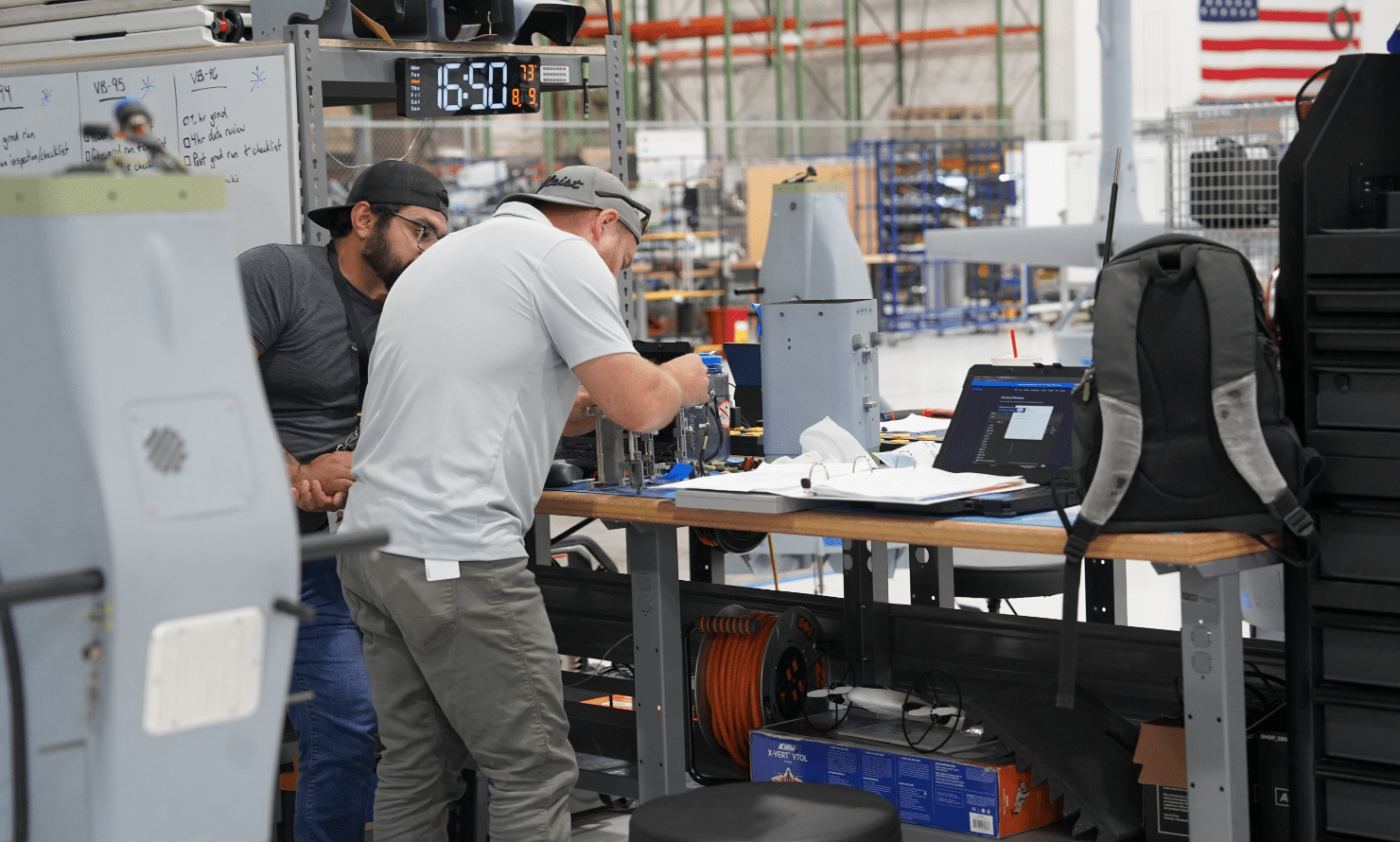

In 2023, our V-BAT production teams have honed a culture of continuous improvement and adaptability, positioning us at the vanguard of the defense industry. As we forge ahead, our production, supply chain, and engineering teams remain central to enhancing V-BAT’s capabilities, working diligently to cement its status as the leader in intelligent and affordable uncrewed aircraft sector.

Our achievements in 2023 have been anchored by a robust planning process. We increased data accuracy and expanded the functionality of our ERP system, created improved shortage analyses, and refined demand management and scheduling protocols. The purchasing team has responded to challenges such as configuration changes and quantity requirements. Their proactive approach to potential shortages ensures minimal disruption to the production line. In the production department, adaptability is the name of the game. The crew consistently addresses challenges, ensuring that every project milestone is met. Their work ethic and dedication have ensured that V-BAT remains a leader in rapid defense tech production. Production rate in August was more than double what it was in January of this year.

Our process engineering team acts as a steady anchor, ensuring that each production step is streamlined and of high quality. Despite Engineering Change Orders (ECOs), their commitment facilitates efficient production. Their efforts have been central to the successful implementation of the One-Piece Flow strategy in 2023, resulting in a 36% reduction in the time required to build the most recent V-BAT compared to the start of the year.

The quality assurance team consistently guarantees that every V-BAT unit meets rigorous industry standards. Working in a fast-paced environment, they prioritize precision and quality, effectively addressing critical issues and reducing critical non-conformances.

Earlier in 2023, we established a comprehensive quality management system, culminating in the achievement of the AS9100 certification. This certification stands as a pledge of our dedication to quality and reliability in all our endeavors.

Lastly, the inventory and kitting team has demonstrated remarkable progress. Through improvements in kit accuracy and part management, they have greatly streamlined our production process.

In the broader defense context, U.S. Deputy Defense Secretary Kathleen Hicks has emphasized the strategic goal of outthinking and outmaneuvering adversaries. With such dedicated teams and refined processes, V-BAT is poised to contribute significantly to this vision, ensuring that we remain at the forefront of defense technology innovation as we look ahead to the next 18-24 months. Our production and supply chain enhancements underscore our capability to scale dramatically. As we look forward, not only is doubling or tripling our year-over-year production feasible, but it’s also the trajectory we’re set on.

Manas and Rick at their desks on the production floor.

Manas Menon is Shield AI’s Vice President of Production and Supply Chain and joined Shield AI in 2017 as employee number 13. He has experience in a variety of startup roles, from founding through mid-stage, doing engineering design work, integration, test and program management. He has 20 patents issued and earned a PhD in Mechanical Engineering from MIT. He also earned two master’s degrees, in ME and EE, from MIT and his BS from UC Berkeley.

Rick Mullen serves as Shield AI’s Director of Manufacturing and Operations. He began his career as a Nuclear-Trained Surface Warfare Officer and later took on key positions at Bell Flight, where he supervised value streams, business continuity, military development projects, and operational excellence. Rick holds an MBA and a M.S. in Mechanical Engineering, both from MIT. He earned his BS in mechanical engineering from CSU Sacramento.